Meet Local Mesa AZ Concrete Contractor Experts for quality concrete solutions

Concrete Driveway Installment In Mesa AZ

Concrete driveway setup in Mesa, AZ, offers a practical option for house owners looking for longevity and visual appeal. The area's environment necessitates a strong, weather-resistant material. Appropriate setup is crucial for longevity and compliance with neighborhood codes. Several variables influence the price and choice of products. Comprehending these components can substantially affect the end result. What should property owners consider before making a final choice?

Advantages of Concrete Driveways

Concrete driveways offer many advantages that make them a prominent choice amongst property owners. Among the primary benefits is their durability; concrete can withstand and withstand heavy loads wear with time, making it perfect for automobile gain access to. Additionally, concrete needs very little maintenance compared to other materials, decreasing long-term prices and initiative for house owners.

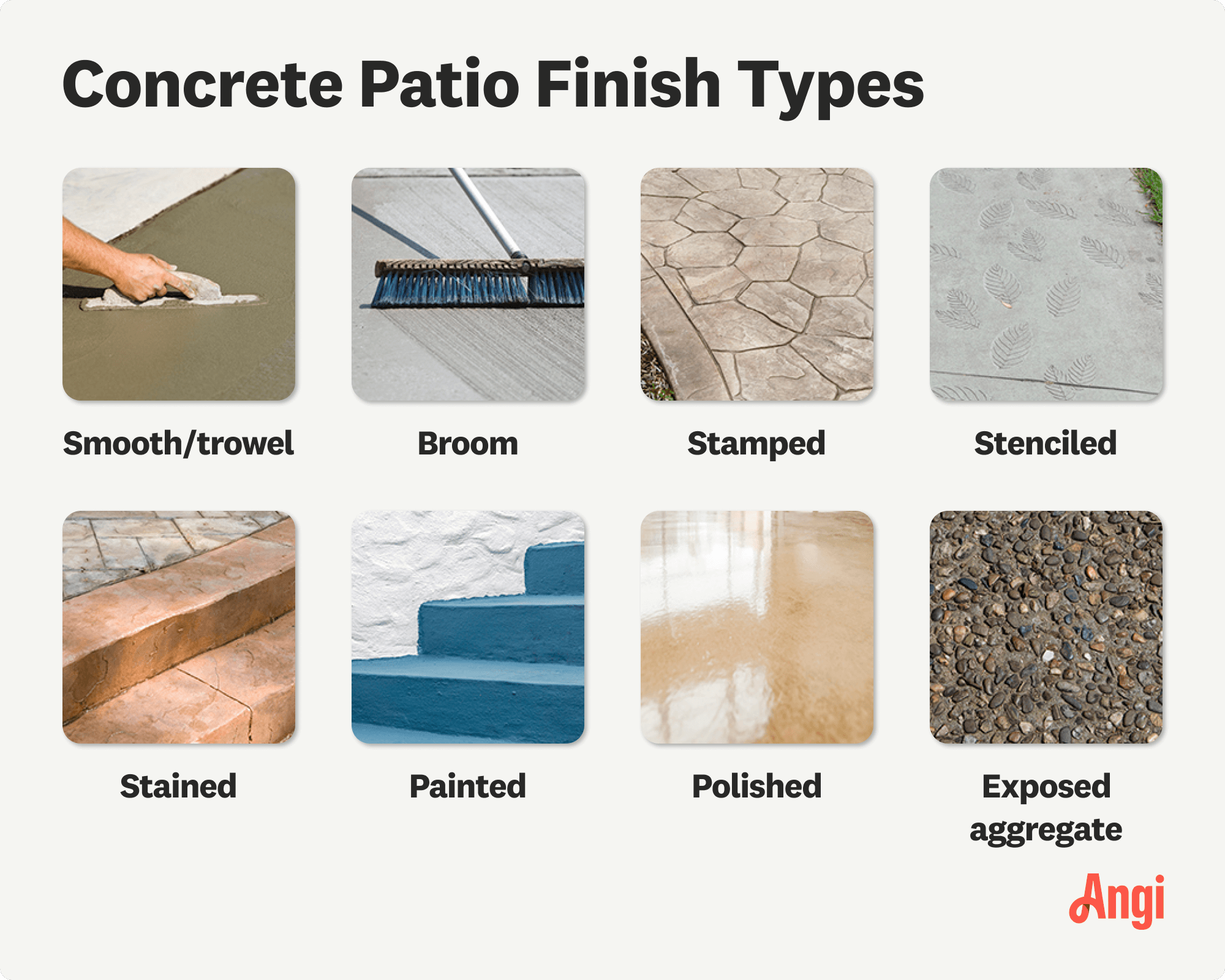

Concrete driveways give a clean, modern aesthetic that improves aesthetic appeal. They can be customized with various coatings, shades, and patterns, permitting home owners to select a design that complements their property.

One more considerable advantage is the material's resistance to weather; concrete is less most likely to split or change in severe temperature levels. Finally, concrete driveways are eco-friendly, as they can be made from recyclable products and add to stormwater monitoring with absorptive choices. In general, these advantages make concrete driveways a appealing and practical selection for homes.

The Installation Process

The installation process of a concrete driveway involves careful site preparation and precise pouring and ending up techniques. The location needs to be removed and rated to assure proper drainage and support. Following this, the concrete is blended, put, and expertly finished to develop a durable and visually pleasing surface.

Website Preparation Tips

Preparing the website is an essential very first step in assuring a successful concrete driveway installation. The process starts with clearing the location of any kind of plant life, debris, or existing pavement. Next off, the ground needs to be dug deep into to the ideal deepness, generally around 4 to 6 inches, to accommodate the concrete and offer a stable base. Correct grading is vital to ensure water drain away from the driveway, preventing future problems. After excavation, a sub-base material, such as gravel, is typically contributed to improve security and support. This layer should be compacted thoroughly. Mounting forms around the perimeter will certainly help have the concrete and specify the driveway's shape. Each of these actions plays an important role in the general success of the installment

Putting and Finishing Methods

When the website is appropriately prepared, the following phase involves putting the concrete. This procedure normally starts with mixing the concrete to achieve the preferred consistency. The concrete is after that transferred to the site making use of a concrete vehicle or wheelbarrow, depending upon accessibility. Pouring need to be carried out in a continuous manner to stop seams, ensuring a consistent surface. Once put, the concrete is spread evenly with a screed to achieve the wanted density.

Finishing methods come next, which might include leveling with a trowel, adding structure for traction, and smoothing the surface. It is important to enable the concrete to establish sufficiently, adhered to by healing, which enhances toughness and sturdiness. Proper putting and completing methods are important for a durable driveway.

Choosing the Right Concrete Mix

Picking the appropriate concrete mix is essential for guaranteeing a resilient and sturdy driveway. The mix can considerably affect the driveway's strength and resistance to ecological variables. Typically, a common domestic driveway calls for a blend with a compressive stamina of at the very least 3,000 psi, though higher strengths, such as 4,000 psi, are often recommended for locations based on heavy lots or severe weather condition problems.

Along with strength, the mix's parts need to be carefully selected. A combination of Portland concrete, sand, crushed rock, and water creates a well balanced mix that enhances sturdiness. Admixtures can likewise be included in improve workability, set time, and resistance to freeze-thaw cycles. It is necessary to talk to experts or local distributors who can advise the best mix based upon particular environment and use variables. Appropriately choosing the best concrete mix establishes the structure for an effective driveway setup.

Maintenance Tips for Longevity

Normal maintenance is crucial for lengthening the life of a concrete driveway. Property owners ought to frequently examine the surface area for fractures and chips, resolving any type of damages promptly to avoid additional degeneration (best concrete contractor in mesa). Cleaning up the driveway with a pressure washer or a mild detergent can remove gunk, dust, and oil, helping to preserve its appearance and stability

Sealing the concrete every few years is also suggested, as it secures versus wetness infiltration, spots, and weather-related wear. Furthermore, eliminating snow and ice without delay during winter months can avoid damage from hefty loads and de-icing chemicals.

Avoiding making use of sharp tools or heavy machinery on the surface area is important, as these can trigger unattractive marks or splits. Assuring appropriate drainage away from the driveway will assist minimize water merging, which can lead to fracturing and erosion over time. Carrying out these upkeep pointers guarantees the driveway continues to be durable and visually appealing for several years ahead.

Cost Aspects to Consider

When preparing for concrete driveway installment, several price elements become critical considerations. The quality of materials picked can considerably affect the overall spending plan, while labor costs and site preparation prices additionally play vital roles in the final price. Comprehending these aspects assists property owners make educated decisions for their jobs.

Product High Quality Effect

Assessing material high quality is vital in establishing the overall expense of a concrete driveway setup. Higher-quality materials, such as superior concrete blends and ingredients, can significantly increase the in advance financial investment. These products commonly give enhanced resilience, resistance to cracking, and improved aesthetic allure, making them a rewarding consideration for property owners. On the other hand, selecting lower-grade materials might reduce preliminary prices yet can result in greater repair and maintenance expenses gradually. Go Here Additionally, the neighborhood environment in Mesa, AZ, may require details material choices to guarantee longevity and performance. Ultimately, picking the right material quality can influence not just the initial installation cost but also the long-lasting value and capability of the driveway.

Labor Expenses Consideration

Labor expenses play a crucial function in the overall expense of concrete driveway setup. Usually, these costs are determined by the intricacy and size of the task. Experienced labor is frequently required to guarantee proper mixing, pouring, and ending up of the concrete, which can raise costs. Additionally, the neighborhood labor market in Mesa, AZ, affects pricing; greater need for professionals might bring about raised rates. Labor prices might likewise vary based on the experience degree of the labor force, with seasoned experts usually charging more. The duration of the project impacts total labor expenditures, as longer setups result in higher overall prices. Property owners ought to acquire numerous quotes to ensure affordable rates for labor in their driveway tasks.

Website Preparation Expenses

Effective website prep work is important for an effective concrete driveway installment, and various expense factors have to be thought about. The first element is the size of the driveway; larger areas call for even more materials and labor. Additionally, the existing website problems play a crucial role; if the ground is uneven or consists of particles, added prices for getting rid of and grading may emerge. Soil kind can also affect prep work prices, as particular dirt conditions may require excavation or support. Neighborhood guidelines and licenses can include to the general expenditures. Finally, the moment of year can affect accessibility and prices of labor and products, making it crucial to prepare accordingly to take care of these prospective prices effectively.

Finding Resident Experts in Mesa

Exactly how can home owners in Mesa assurance they choose the right experts for their concrete driveway setup? One efficient approach is to look for referrals from friends, family members, or regional area teams. Individual experiences commonly offer useful understandings right into the integrity and high quality of solution offered by specialists. Furthermore, home owners need to research on the internet evaluations and scores on systems like Yelp or Google to gauge the track record of possible specialists.

It is also wise to verify credentials, including licenses and insurance policy, making certain that the specialists are qualified and responsible. Getting several quotes can help house owners contrast pricing and services, causing notified choices. In addition, going to finished projects or requesting references can showcase the contractor's workmanship. Lastly, involving with regional home renovation shops or building supply firms might produce additional referrals for respectable specialists in the Mesa location, assisting homeowners make an audio choice for their concrete driveway installation.

Regularly Asked Questions

For How Long Does Concrete Require To Cure After Setup?

Concrete typically takes concerning 28 days to fully cure after installment, accomplishing its maximum strength. It can be walked on after 24 to 48 hours, depending on environmental conditions and particular mix made use of.

Can I Set Up a Concrete Driveway in Winter Months?

Yes, a concrete driveway can be installed in wintertime, however precautions have to be taken. Cold temperature levels can reduce curing, so using additives and preserving appropriate insulation are important for guaranteeing an effective installment throughout cooler months.

What Colors Are Offered for Concrete Driveways?

A selection of colors are offered for concrete driveways, consisting of conventional gray, natural browns, deep blacks, and lively shades like blue or red. Additionally, tarnishing techniques can boost the shade and visual appeal further.

How Do I Fix Fractures in My Concrete Driveway?

To fix cracks in a concrete driveway, clean the location thoroughly, apply a concrete patching compound, and smooth it over with a trowel. Allow it to treat according to the producer's guidelines for finest outcomes.

Exist Eco-Friendly Options for Concrete Driveways?

Yes, eco-friendly stamped concrete overlay pool deck options for concrete driveways exist. These include recycled concrete aggregates, absorptive concrete, and utilizing sustainable production approaches. Such choices decrease environmental influence while keeping longevity and visual allure in driveway installments.

The concrete is after that carried to the site making use of a concrete truck or wheelbarrow, depending on access. Evaluating worldly high quality is vital in figuring out the general expense of a concrete driveway installment. Labor costs play a crucial function in the overall expense of concrete driveway installation. To repair useful content splits in a concrete driveway, tidy the location completely, apply a concrete patching compound, and smooth it over with a trowel. These include recycled concrete aggregates, permeable concrete, and utilizing sustainable manufacturing techniques.